Grants related:

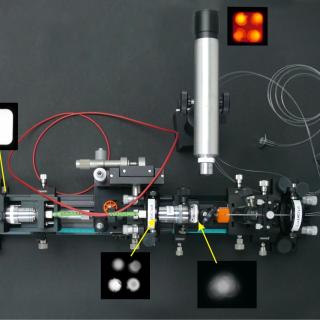

The IAC Fibre Optics Laboratory has as main objective the preparation, assembly and polishing of optical fibre bundles for its application to astronomical instrumentation. Its surface is about 12 m2. The assembly of the bundles is carefully done manually in order to preserve the correct functionality and characteristics of the fibres. Usually, ancillary tools are designed to facilitate the assembly, since it is common to work with very thin fibres with cores up to 50 microns in diameter. The assembly of the bundles consists of coupling the fibres to their mechanical interfaces. These interfaces are used for their direct integration into the astronomical instrument or as a tool for their subsequent polishing. For this, resin-type adhesives with long curing times are used. These long cure times are necessary so that the stresses produced on the fibres are minimized. To ensure the transparency and preservation of the characteristics of the light entering the fibre, an optical quality polishing of the ends of each fibre is carried out. To make this polishing two machines are available, one is metallographic and the other is optical polishing machine. The polishing process can vary considerably depending on the requirements. Normally and in a generic way, in the initial phase a fine-grained (1,200) sandpaper is used as an abrasive to eliminate the main defects of the surface to be polished. From here begins a process of mechanical polishing with diamond paste abrasives with different grain sizes up to a size of 0.1 microns. During this process the flatness and the quality of the optical finish of the fibre faces are frequently verified until the required results are obtained. To finish, the quality of the manufactured bundles is verified in the Optical Laboratory. Its behavior in optical efficiency, focal ratio degradation and scrambling, both in the near and distant fields, are checked. Part of the equipment of this laboratory has been financed by ERDF funds.