The Instituto de Astrofísica de Canarias (IAC), through its Optics Department and the Center for Advanced Optical Systems (CSOA), is taking a new step towards becoming one of the largest manufacturers of optical elements for large telescopes in the world. This is after the consolidation of a new infrastructure for optical production that will allow it, from now on, to take care of all the stages in the manufacture of mirrors for large telescopes, from the cutting of parts to polishing and coating, as well as the manufacture of other precision optical elements for astrophysical instrumentation.

After the latest additions, the Center for Advanced Optical Systems (CSOA) marks the beginning of a new era in the production of large-scale optical elements at the IAC and in Spain, and opens a door to new opportunities for collaboration in telescope manufacturing and other R&D projects.

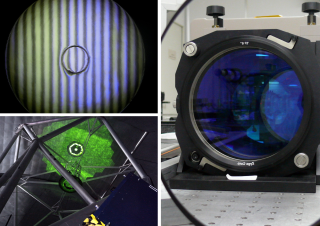

CSOA's kick-off begins with the reception of three new technologically advanced machines, which are already installed in the laboratories. The optics team is testing all the possibilities and expects to have the first samples in the next few months.

The most remarkable addition is the large-surface polishing machine installed in the IACTEC building in La Laguna. This polishing machine will be a fundamental part of CSOA 1.5 (Center for Advanced Optical Systems for substrates up to 1.5 meters) and, for the first time, will allow the manufacture of large mirrors with the curvature and precision suitable for today's large telescopes. The surface finish is such that if the mirror were the size of the island of Tenerife, the tallest mountain would be no bigger than a human hair. "This is the first link in the creation of a laboratory with a capacity that is only within the reach of a few centers in the world," says José Luis Rasilla, head of the IAC's Optics Department and manager of the CSOA project.

But this is not the only improvement to the CSOA equipment. At the headquarters of the IAC in La Laguna are already in operation two other new machines for the manufacture of medium-sized optical elements (up to 0.5 meters): a cutting machine for glass with semi-automatic sawing and a generator, which together allow precise manufacture of optical materials of any shape and curvature.

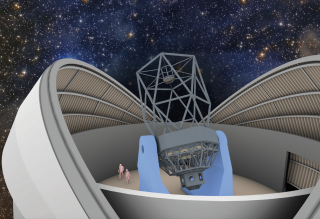

"We have taken a major step forward in testing the enormous versatility of the new polisher. In the coming months we will take full advantage of this cutting-edge technology to familiarize the team with it and prepare for the first challenge ahead: the fabrication of the primary mirror segments of the New Robotic Telescope (NRT)," says Carlos Gutiérrez, NRT Principal Investigator.

When completed, the NRT will be the world's largest robotic telescope with a total diameter of 4 meters. Thanks to its fully autonomous mode of operation, its lightness and pointing speed, it will be able to capture precise images of transient events: phenomena that evolve very rapidly in time, such as gamma-ray bursts or supernovae, which still present many enigmas and for which the first moments after detection can be crucial to our understanding.

The NRT is expected to be the first of a series of ambitious projects in collaboration with other research centers. The goal is to widen the scope of precision optics and open new doors to projects beyond astronomy, such as the laser industry, solar energy harvesting or optoelectronics.

This infrastructure will be completed with another polishing machine for small substrates, an ion beam ultropolishing system and an optical coating system for mirrors up to 2 meters in diameter, which are scheduled for delivery in mid-2024.

This moment is just the beginning of a series of challenges that is expected to establish CSOA, and the IAC, as an international reference center in precision optics. "We look forward to testing all the possibilities offered by this new machinery and to the opportunities that will arise as we progress further in our projects," concludes Rasilla.