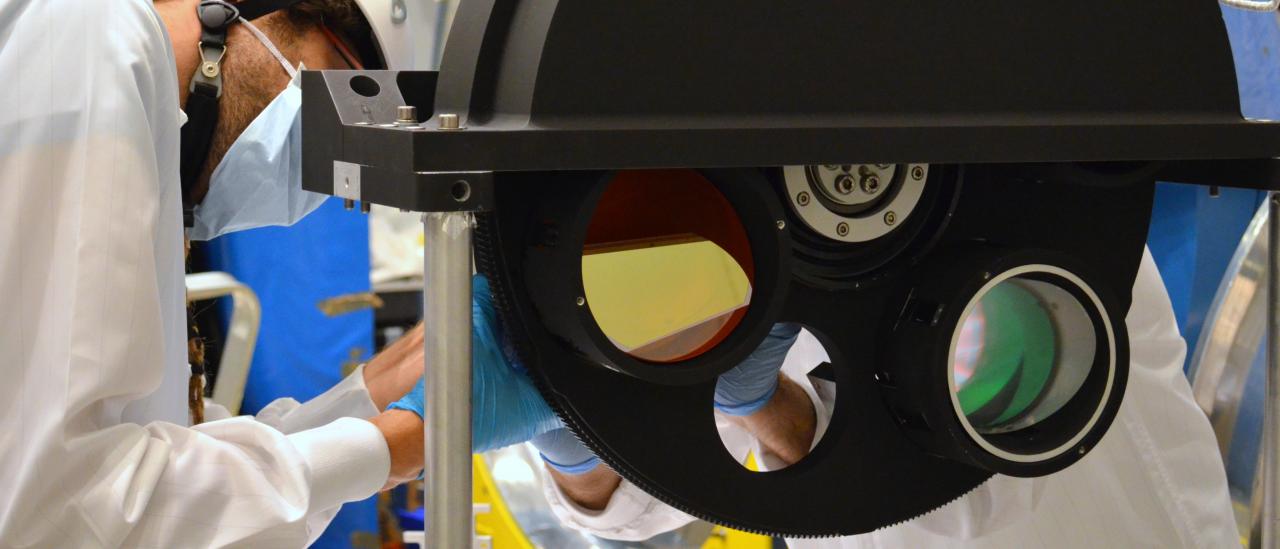

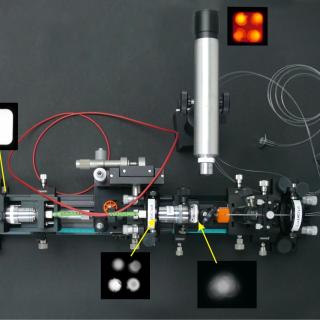

The mechanical design process of a specific astrophysical instrument begins with the generation of the technical specifications of its mechanical systems. Next, we go through the stages of conceptual design, preliminary and detailed design, with the help of specialized software for 3D design and finite elements analysis and calculation. This allows to complete the set of mechanical characteristics, geometry, materials, treatments, finishes, etc., to be used in the different subsystems, as well as the tolerances assigned to each of them, in order to generate the manufacturing drawings and specifications. Subsequently it is necessary to follow up the manufacture of the components and, after dimensional verification, it is undertaken the assembly, integration and final verification of the different subsystems as well as the global system, both in the laboratory and in the telescope. The mechanical engineering team of the IAC already has numerous examples of scientific instrumentation whose structures, mechanisms and opto-mechanical systems have been designed, manufactured and verified in their facilities.